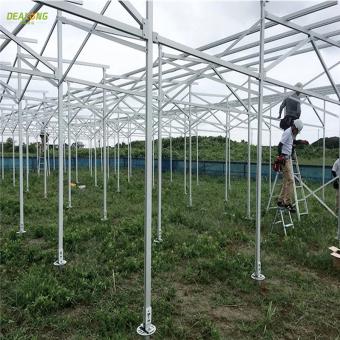

Solar Ground Mounts are designed for open field grounds including flat and slope. Main components are highly pre-assembled in our factory, which saves you much on-site installation time and costs.

View MoreWe design and produce different type solar PV mounting structures including solar rooftop mounting system, solar ground mounting system, solar carport, solar farm, solar green house and ground screw foundation.

The diamond-shaped expanded steel mesh is made of high-quality low-carbon steel plate through punching and stretching to form a expanded steel mesh sreen. Available colors:

Solar panel ground mounts are pre-assembled at factory to save your installation time and cost

1.Model NO:AL-20201110-01 2.Product name: Solar Carport Mounting System 3. Material:aluminum & stainless 4. Max wind speed:60m/s 5. Snow load: up to 1.4kn/m2 6. Installation angle:10°~60° 7. Anti-corrosive:anodized 8. MOQ: 10000 Watt 9. Payment Item: bank T/T, paypal, western union 10. Lead time: 10-15 days after payment

Easy to install and no cutting and welding are needed at installation site,saving your time and costs

1. Product Name: Solar Panel Roof Mounting 2. Material: Stainless Steel 304 3. Plate: L140*W33*T4mm 4. Weight: 0.56kg 5. Surface: Sandblasted 6. Type: Adjustable 7. Components: Hook+Bolt+Nut 8. MOQ: 1000 Pieces 9. Payment Item: bank T/T, paypal, western union 10.Lead time: 10-15 days after payment

1.Model NO:AL-20201110-07 2.Product Name:Hot Dip Galvanized Foundation Helical Blade Screw Pile 3.Material:Q235B,Q195 Steel 4.Surface Treatment:Hot dip galvanizing 5.Application:Solar mounting system,fence, wooden house 6.Certificates:ISO9001,ISO1461-1999 7.Production Capacity: 1,000,000 Piece/Pieces per Month 8.Lead Time:10-15 days. 9.MOQ:100 pcs

1.Model NO:AL-20201111-01 2.Product name:Mounting Carport Structure 3. Material:aluminum & stainless 4. Max wind speed:60m/s 5. Snow load: up to 1.4kn/m2 6. Installation angle:10°~60° 7. Anti-corrosive:anodized 8. MOQ: 10000 Watt 9. Payment Item: bank T/T, paypal, western union 10. Lead time: 10-15 days after payment

Mar . 2023

The 763.7 KW project products exported to Denmark have been packaged and are ready to ship. This project includes solar ground mounting system, rooftop mounting brackets, and earth screws. Established in 1992, Shuangheng Group is located in Quanzhou city near one of China’s international transportation hubs. Its garden-style industrial park covers an area of 13,000 acres with more than 1500 employees. We always follow our"integrity, law-abiding,people-oriented, innovation and pursuit of excellence” core values. We design and produce different types of solar PV mounting structures including solar rooftop mounting systems, solar ground mounting systems, solar carports, solar farms, solar greenhouses, and ground screws as foundations.

View MoreIn the solar energy industry, the safety of power stations has always been the focus of the industry. The solar mounting system supports the entire power station. Once damaged, it will not only stop normal power generation but also even cause permanent damage. In recent years, there are still many examples of solar mounts collapsing and being damaged due to quality problems. Let's talk about "How to choose a high-quality solar PV mounting system?" First, concern design capability The application scenarios of photovoltaic supports are complicated: climate, geology, and environmental factors of the project site are different, so a custom design is required, which involves the calculation of many professional values. Manufacturers with excellent design capabilities can obtain more accurate values through their professional calculation and rich project experience, so the designed projects are safer and more reasonable. Choosing a solar panel mounting bracket manufacturer with excellent design capabilities can make sure the safety of power stations and help customers reasonably control costs. Second, concern production capability The quality problems in the manufacturing process cannot be ignored. It is reported that some low-priced products on the market have defects in terms of material selection, craftsmanship, and quality control. Some anti-corrosion treatment is improper. These defects not only affect the visual effect but also greatly shorten service life and increase the maintenance cost of power stations. If a company has a small production capacity or even has not his own production base, it is likely to be difficult to guarantee quality. Therefore, when purchasing solar panel mountings, it is necessary to fully examine the production capability, including the scale of the production base(integrated production or not), production equipment, testing facility, and production capacity. On-site inspections are recommended if possible. Established in 1992, Shuangheng Group is located in Quanzhou city, which is near one of China’s international transportation hubs. Its garden-style industrial park covers an area of 13,000 acres with more than 1500 employees. We always follow our"integrity, law-abiding, people-oriented, innovation and pursuit of excellence” core values. We design and produce different types of solar PV mounting structures including solar rooftop mounting systems, solar ground mounting systems, solar carports, solar farms, solar greenhouses, and ground screws as foundations.

View MoreThe products sent to South Korea are being loaded and are expected to arrive at Xiamen Port today. Established in 1992, Shuangheng Group is located in Quanzhou city, which is near one of China’s international transportation hubs. Its garden-style industrial park covers an area of 13,000 acres with more than 1500 employees. We always follow our"integrity, law-abiding,people-oriented, innovation and pursuit of excellence” core values. We design and produce different types of solar PV mounting structures including solar rooftop mounting systems, solar ground mounting systems, solar carports, solar farms, solar greenhouses, and ground screws as foundations.

View More